January 13, 2016

For Immediate Release…

New Adjustable Motor Base Greatly Increases Life Cycle

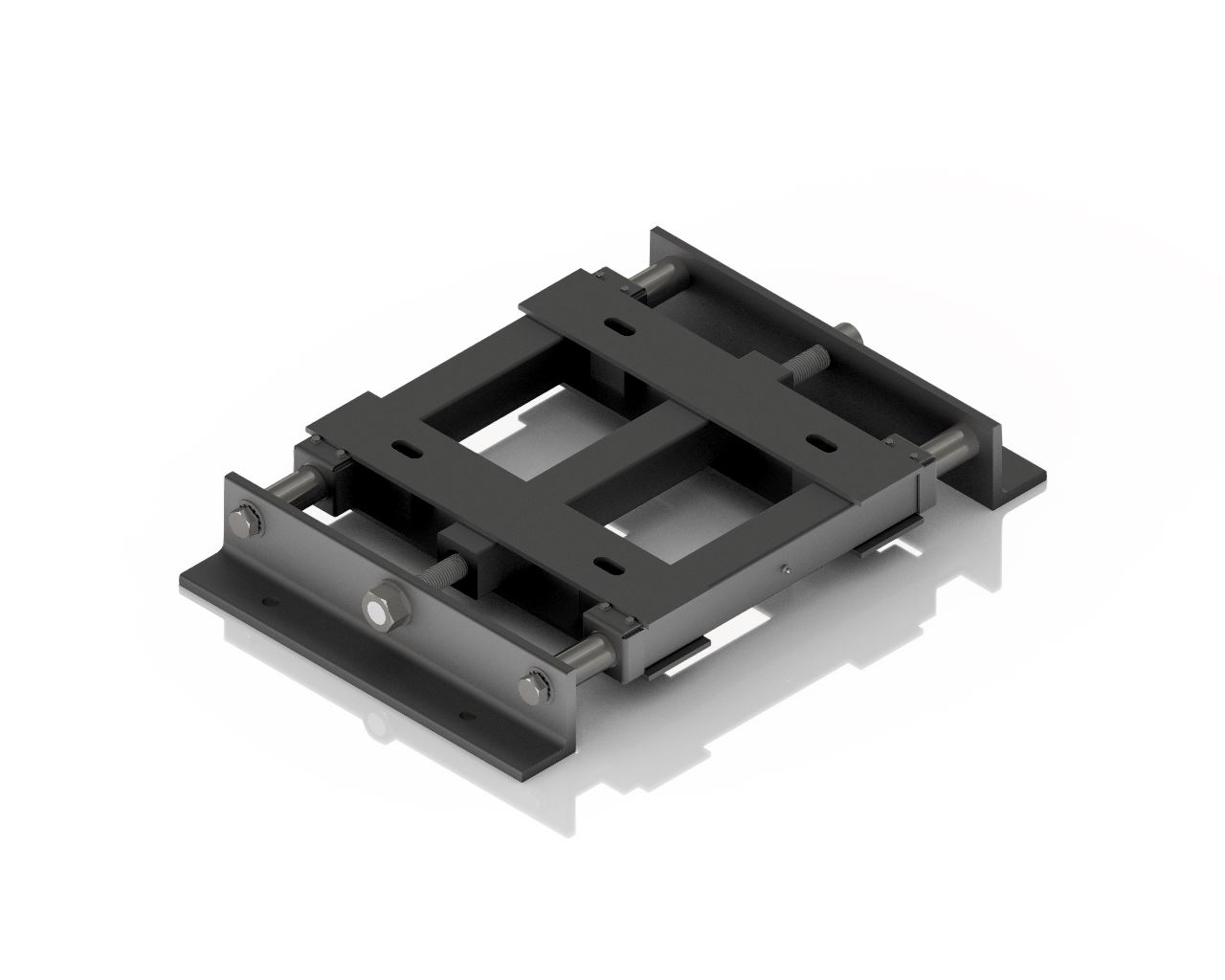

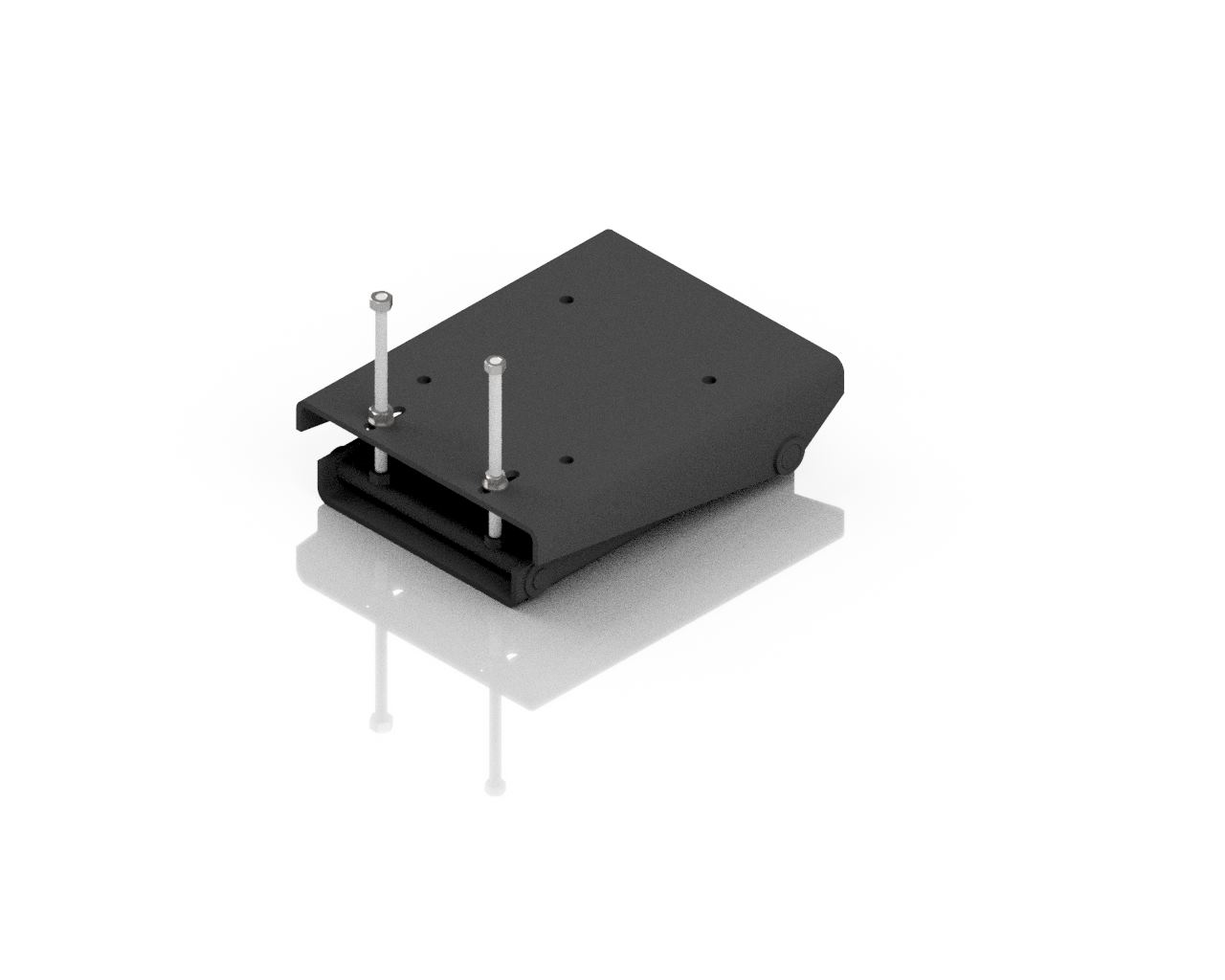

Overly Hautz Company (OHC) has introduced a new patent-pending screw adjusting mechanism to their line of standard motor bases. This new mechanism greatly increases the life cycle of OHC’s standard motor bases, saving money through longer product life cycle and significantly less production down time. Factory tests conducted have shown a 5-to-9.5-times longer life cycle than a competitive motor base.

Tests were conducted with OHC’s new standard motor bases and competitive motor bases. The tests determined the number of drive belt changes that could be performed before the belt-tightening screw mechanism on the motor base failed. A motor-base failure would result in the need to replace the motor base, causing added expense as well as a production shut down.

These tests were conducted on a ‘motor, motor base, and load’ test stand with three various size motor bases tested. The bases tested were for NEMA electric motor frame sizes 254, 324, and 444. These three frame sizes cover a majority of field applications for large motors. 3D Engineering Solutions of Cincinnati, Ohio has verified and validated the tests conducted and agrees with the results shown.

Life Cycle Testing

Belt Changes with Standard Adjustable Motor Bases

|

Frame Size NEMA Electric Motor |

Number of Belt Changes |

Multiple Increased Lifespan Using an Overly Hautz Motor Base |

|

|

Overly Hautz’s Motor Base |

Competitor’s Motor Base |

||

|

254 |

52 |

5.5* |

9.5 x |

|

324 |

60 |

12* |

5.0 x |

|

444 |

25 |

3.5* |

7.1 x |

* Average of results for two bases

Each test was conducted with three different motor bases. Two bases from competitors and one from OHC. All bases were tested to belt-tightening screw thread failure, causing mo- tor base failure.

(30)

Industrial Marketing Communications

Richard D. Cost, 2226 Tampico Trail, Bellbrook, OH 45305 * Phone: 937.848.4772 – Cell: 937.657.4150 – Email: rcost5@woh.rr.com